Another milestone on the D&H!

Today I completed another milestone on the D&H.

I have now completed the light installation.

The layout now has 11 x 4ft T5 fluro's, 12 x 2ft T5 Fluro's and no less than 27 x T8 4ft fluro's.

The layout is now basking in the light and it is AWESOME!.

I have also been working on mounting the 28 Loconet attached devices that will drive the turnouts, manage the block detection and drive the signals for the layout.

I have been mounting the modules on pre painted 6mm MDF and terminating the boards on screw terminals for easy install under the layout.

I had planed on building the staging, however, I figured to save some time and pain in terms of wiring down the track, I figured I would install the electronic laden control boards around the layout and connect them into the loconet bus, track power bus, accessory bus power before installing the layout decks.

I have not quite finished doing the terminations on the boards, but all the electronics is now mounted and terminal strips are installed. Im about 1/2 way through the terminations.

Here are a few examples. There are 14 control boards in total.

The Delaware & Hudson Rail Road 4th Sub is based on the Delaware & Hudson Railroad in New York state (USA) in the Whitehall area on the old D&H. The layout is N scale and I will use Digitrax DCC to run the layout. I am building the layout with full block signalling close to prototypical to the Delaware & Hudson per the D&H rule book dated 25th April 1948. Please enjoy the progress.

Tuesday, 24 December 2013

Thursday, 12 December 2013

Cork and wiring rough in

Its all in the planing.!

Sometimes, the success of a railroad is all in the planing..

This week, I procured 35 sheets of 3mm cork and 10 sheets of 1.5mm cork that is to be used between the track and the ply base of the layout.

I then set off to my fathers factory where a 20 ton guillotine is available for the rapid slicing of the cork. Unfortunately the blade is not as sharp as it could be and the cut was not as clean as I needed. So, I left a number of sheets at the factory, as the blade is to be replaced in the next week or so to then be cut.

In the mean time, I have been planing the multiple main bus wiring for the track power, the auxiliary device power, Loconet and also the phone system.

This week, I have managed to install the main bus wires for all of the above. I soon found that I needed 40 meters of Loconet cable and similar amounts of wire for the phone, track power and aux power bus.

I have also looked at the requirements to drive all my signals, turnouts and block detection.

I have now planned where all those devices need to be installed around the layout. All 28 devices excluding the DCS100!.. See the plan for what I mean..

In the plan all turnouts are managed via a loconet device, all main line and loop blocks are detected including separate OS sections for each of the turnout interlockings.

There will be 9 power districts (only so that when a short is encountered in a town, the rest of the layout is not effected.) All this will be run from 1 x DCS100.

I will now set about installing the loconet aux devices on timber and pre wiring them with terminal blocks before I install the decks of the layout. Once ready I will install them before screwing down the decks that I have already cut. (to make the install easier!).

Stay tuned for the next update.

Sometimes, the success of a railroad is all in the planing..

This week, I procured 35 sheets of 3mm cork and 10 sheets of 1.5mm cork that is to be used between the track and the ply base of the layout.

I then set off to my fathers factory where a 20 ton guillotine is available for the rapid slicing of the cork. Unfortunately the blade is not as sharp as it could be and the cut was not as clean as I needed. So, I left a number of sheets at the factory, as the blade is to be replaced in the next week or so to then be cut.

In the mean time, I have been planing the multiple main bus wiring for the track power, the auxiliary device power, Loconet and also the phone system.

This week, I have managed to install the main bus wires for all of the above. I soon found that I needed 40 meters of Loconet cable and similar amounts of wire for the phone, track power and aux power bus.

Sorry for the poor pictures.. But you get the idea!

I have also looked at the requirements to drive all my signals, turnouts and block detection.

I have now planned where all those devices need to be installed around the layout. All 28 devices excluding the DCS100!.. See the plan for what I mean..

In the plan all turnouts are managed via a loconet device, all main line and loop blocks are detected including separate OS sections for each of the turnout interlockings.

There will be 9 power districts (only so that when a short is encountered in a town, the rest of the layout is not effected.) All this will be run from 1 x DCS100.

I will now set about installing the loconet aux devices on timber and pre wiring them with terminal blocks before I install the decks of the layout. Once ready I will install them before screwing down the decks that I have already cut. (to make the install easier!).

Stay tuned for the next update.

Sunday, 8 December 2013

Main deck and staging construction

Raisers and more raisers.

Now that I have decided that the LED lighting is not going to be bright enough for the layout and the only option is Fluro's, I now need to source enough fluro's to complete the layout.

As this is going to take a week or so, I decided that I would make a start on the main decks at North Creek and Plattsburgh and also the staging for the North and South ends.

Earlier this week I completed all the raisers at North Creek and Plattsburgh. Both of these towns dont have staging tracks below them so I knew I could make a start. During the week I completed the raisers and then today I completed the main decks at both towns as well as the majority of the deck for the North and South staging.. Now to complete the road beds from staging to the main deck of the layout some 300mm higher than staging.

Here are a few progress pictures.

Now that I have decided that the LED lighting is not going to be bright enough for the layout and the only option is Fluro's, I now need to source enough fluro's to complete the layout.

As this is going to take a week or so, I decided that I would make a start on the main decks at North Creek and Plattsburgh and also the staging for the North and South ends.

Earlier this week I completed all the raisers at North Creek and Plattsburgh. Both of these towns dont have staging tracks below them so I knew I could make a start. During the week I completed the raisers and then today I completed the main decks at both towns as well as the majority of the deck for the North and South staging.. Now to complete the road beds from staging to the main deck of the layout some 300mm higher than staging.

Here are a few progress pictures.

Plattsburgh

Plattsburgh on the right and North Creek on the left

North Creek

North Creek from the other end

The end of North Staging

North Staging

North Staging

North Staging

Plattsburgh from the other end

Raisers ready for Willsboro (after I add the deck for the staging line below it)

South Staging

South staging

South staging

Thanks for visiting.

Monday, 2 December 2013

More on LED Strips for lighting

When is there enough light?

After my last post I managed to source LED strips that are in the 5000K to 5500K range and very agreeable to the eye.

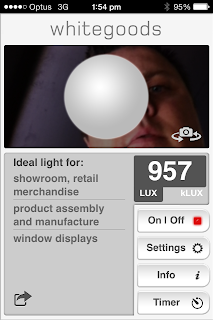

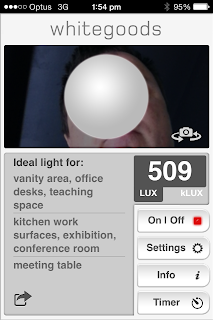

Now I know the colour I want / need, the next key issue is much much light is enough light, ie what is the light reading from each of the

solutions such as Fluro's vs LED Light strips.

The key to this whole thing is a light meter. Where can I loan one from.. Then I did a search on the Apple Apps store and found a light meter app for my iPhone (for free!). YEY!..

While is may not be 100% accurate, it will be close and it does give me a relative reading for each solution.

So here is what I found:

The fluro's when tested at main deck level (being 1m from the fluro to the main deck) read out at on average 2,500 to 3,000 lux. (These are the cool white Fluro or 4000K)

The single strip of LED's when measured from the main deck to the bottom of the valance being 600mm read out at 400lux (These being the 5500K LED Strips that we will from now on call Pure white)

If I add all 3 strips of LED's (cool white, Pure white and warm white, remembering that the colour of the light is not the issue here but what I happen have have on hand) I get up to 950lux

If I add the warm white and the pure white I get to 500 lux so OK for kitchen work and meeting table lighting.

If I add the cool white (read that as the blue 6500K one) and the pure white then I get to 600lux so about the same as the 2 above but more light.

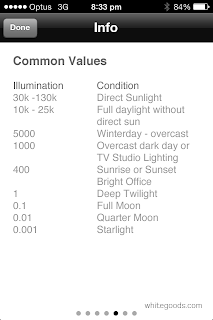

The app recommends what the light level is suitable for.

With 3 rows of LED's it is enough for studio lighting at around 900 lux.

400 lux is about sunrise / sunset, and a bright office.

So if 3 rows of LED's are needed (all the same colour) then the hyp pocket is still happy as it is still cheaper than having to use just Fluro's

After my last post I managed to source LED strips that are in the 5000K to 5500K range and very agreeable to the eye.

After a discussion with a bunch of friends at an operating session recently re the LED's vs Fluro's I did some more

testing over the weekend.

The key to this whole thing is a light meter. Where can I loan one from.. Then I did a search on the Apple Apps store and found a light meter app for my iPhone (for free!). YEY!..

While is may not be 100% accurate, it will be close and it does give me a relative reading for each solution.

So here is what I found:

The fluro's when tested at main deck level (being 1m from the fluro to the main deck) read out at on average 2,500 to 3,000 lux. (These are the cool white Fluro or 4000K)

The single strip of LED's when measured from the main deck to the bottom of the valance being 600mm read out at 400lux (These being the 5500K LED Strips that we will from now on call Pure white)

If I add all 3 strips of LED's (cool white, Pure white and warm white, remembering that the colour of the light is not the issue here but what I happen have have on hand) I get up to 950lux

If I add the warm white and the pure white I get to 500 lux so OK for kitchen work and meeting table lighting.

If I add the cool white (read that as the blue 6500K one) and the pure white then I get to 600lux so about the same as the 2 above but more light.

The app recommends what the light level is suitable for.

Also see the pic with the common values.

Basically my fluro's are at about 3,000 lux or 3kLUX that is basically

daylightWith 3 rows of LED's it is enough for studio lighting at around 900 lux.

400 lux is about sunrise / sunset, and a bright office.

So the million dollar question is, how much light is enough?

I did my tests at the level that the main deck will be and not at the base

board level (as the light would be less at the 1100mm mark compared to the

1400mm level.)

I have now enlisted the help of a friend that has already used LEDs on his layout to do some light testing and see what he counts as acceptable light from the Iphone app.

So if 3 rows of LED's are needed (all the same colour) then the hyp pocket is still happy as it is still cheaper than having to use just Fluro's

3 rows of LED's is just under $500 where as 26 x 1.2m fluro's is $780 (@$26

each)

I will keep researching!...

Thursday, 14 November 2013

Researching Lighting

LED Technology for Lighting

Now that I have installed all the Fluro light fittings that I have on the layout, I now need to find an economical way to light the rest of the layout.

I have been watching the LED technology come along in leaps and bounds over the last few years and have found that with the new 5050 type LED (5mm x 5mm) in white can effectively light the layout. These 5050 type LED's come in 5 meter lengths with 300 LED's per the 5 meters.

I found a number of options on eBay and ordered a warm white with a colour temperature of 2800K to 3000K and a Cool white with a colour temperature of 6300K to 7000K.

After I received them I did some testing (See pictures) and found that the "warm white" to be too yellow and the "Cool white" to be far too blue.

After a heap of research and a heap of help from Ron McFarlane on the subject.

Ron sent me these pictures to show the colour temperature ranges.

The Fluro's that I have in the room have a colour temp of 4000K so could be a bit yellow but look OK to me (at present.)

After doing some more research I found a LED supplier that has what he calls "Pure white" 5050 LED's in the same 5 meter strip and he suggests that they have a colour temperature of 5500K.

I have now arranged to get a 5 meter length from that supplier and will do more testing. The advantage of using the local supplier, all be it slightly more expensive, is that if I don't like what I get from him I can return them. Where as, purchasing from eBay from Hong Kong, the return process is not so easy and the guarantee of the colour temperature is also hit and miss..

I will do some more testing over the next 24 hours with the 5500K LED's and see how that goes.

There is a significant cost advantage in using the 5m LED strips as 5 meters of LED including a power supply is about the same price and 1 x 1.2 meter fluro fixture. Not to mention the cost to run them is far cheaper.

Stay tuned for more updates.

Now that I have installed all the Fluro light fittings that I have on the layout, I now need to find an economical way to light the rest of the layout.

I have been watching the LED technology come along in leaps and bounds over the last few years and have found that with the new 5050 type LED (5mm x 5mm) in white can effectively light the layout. These 5050 type LED's come in 5 meter lengths with 300 LED's per the 5 meters.

I found a number of options on eBay and ordered a warm white with a colour temperature of 2800K to 3000K and a Cool white with a colour temperature of 6300K to 7000K.

After I received them I did some testing (See pictures) and found that the "warm white" to be too yellow and the "Cool white" to be far too blue.

After a heap of research and a heap of help from Ron McFarlane on the subject.

Ron sent me these pictures to show the colour temperature ranges.

The Fluro's that I have in the room have a colour temp of 4000K so could be a bit yellow but look OK to me (at present.)

After doing some more research I found a LED supplier that has what he calls "Pure white" 5050 LED's in the same 5 meter strip and he suggests that they have a colour temperature of 5500K.

I have now arranged to get a 5 meter length from that supplier and will do more testing. The advantage of using the local supplier, all be it slightly more expensive, is that if I don't like what I get from him I can return them. Where as, purchasing from eBay from Hong Kong, the return process is not so easy and the guarantee of the colour temperature is also hit and miss..

I will do some more testing over the next 24 hours with the 5500K LED's and see how that goes.

There is a significant cost advantage in using the 5m LED strips as 5 meters of LED including a power supply is about the same price and 1 x 1.2 meter fluro fixture. Not to mention the cost to run them is far cheaper.

Stay tuned for more updates.

Thursday, 7 November 2013

Dark ceiling and light

Let there be light!

Last week I set to painting the ceiling where the walk ways are from sky blue to black.

Now the valance is installed and the walk way ceiling is painted the room is starting to look really nice.!

Now that the valance is done and the painting is done, it is time to start installing or reinstalling the lights.

As I set the lights close to the wall to enable the main part of the construction to be completed, they were going to be in the wrong place (aka to close to the wall and not near the back of the valance). I then removed all the lights that had been installed and set about installing the lights just behind the valance. This will ensure that any trains near the front of the layout have adequate light and wont cast shadows.

As I only have enough fluro's for about 1/3rd of the room, I set to installing them up to a natural dividing point. The rest of the layout room will be bathed in light from 5 meter LED strips.

The LED strips have 300 x 5050 type cool white LED's within the 5 meter length. These new LED's are fantastic. They really light up the part of the layout nicely. As I only have a test 5m roll that is warm white (I goofed when I ordered it) I temporarily clipped it up under the valance. I'm very confident that I only need 1 line of these LED strips behind the valance around the rest of the layout and for $20 per 5m strip they are significantly cheaper than fluro lights.

Here are a few progress pics of the lights (fluro's) that are installed now.

I have ordered some cool white LED strips via eBay and am eagerly waiting for them to arrive..

Soon it will be time to start on the staging.. Im looking forward to that!...

Stay tunned for more updates.

Last week I set to painting the ceiling where the walk ways are from sky blue to black.

Now the valance is installed and the walk way ceiling is painted the room is starting to look really nice.!

Now that the valance is done and the painting is done, it is time to start installing or reinstalling the lights.

As I set the lights close to the wall to enable the main part of the construction to be completed, they were going to be in the wrong place (aka to close to the wall and not near the back of the valance). I then removed all the lights that had been installed and set about installing the lights just behind the valance. This will ensure that any trains near the front of the layout have adequate light and wont cast shadows.

As I only have enough fluro's for about 1/3rd of the room, I set to installing them up to a natural dividing point. The rest of the layout room will be bathed in light from 5 meter LED strips.

The LED strips have 300 x 5050 type cool white LED's within the 5 meter length. These new LED's are fantastic. They really light up the part of the layout nicely. As I only have a test 5m roll that is warm white (I goofed when I ordered it) I temporarily clipped it up under the valance. I'm very confident that I only need 1 line of these LED strips behind the valance around the rest of the layout and for $20 per 5m strip they are significantly cheaper than fluro lights.

Here are a few progress pics of the lights (fluro's) that are installed now.

I have ordered some cool white LED strips via eBay and am eagerly waiting for them to arrive..

Soon it will be time to start on the staging.. Im looking forward to that!...

Stay tunned for more updates.

Thursday, 31 October 2013

Let there be valance

Valance install.

Over the last week or so I have been preparing the 2400 x 1200 x 3mm MDF sheets. They all needed to be painted white on one side (to reflect the light) and black on the opposite side.

Once I completed painted about 12 sheets of the MDF I then cut them into 400mm wide x 2400 long sections. As each sheet is 1220 wide I was able to get 3 x 400mm wide sheets from each larger sheet.

At this point I am super thankful for the help of my wife Michelle to helping feed the 12 sheets multiple times through the ever reliable Triton workbench.

The end result being 36 sheets ready to be installed.

As I planed to install the valance my self I found a I needed a 2nd pair of hands holding up the 2400mm long sheet. I quickly devised a jig using a old Black and Decker saw bench, a bunch of clamps and some timber. This mean that I was able to position one end of the valance near the ceiling and in roughly the correct spot and then start at the opposite end and screw the valance to the mounting timber I had installed some weeks ago. Got to love it when a plan comes together.!

Late yesterday and last night I installed all 36 odd sheets that were needed.

Then I cut up some extra smaller sheets that I then glue to the back of the valance to form a strong joint or connection between the each valance sheet. To do this I simply cut pre painted MDF sheets to 360mm x 200mm. Then with large amounts of wood glue, a few clamps and timber to hold it all in place I proceeded to connect all the sheets together.

Per the pictures I'm still working my way around the valance and gluing each part.

The next step is to paint all the silver screws that hold it to the mounting timber and to paint the walk ceiling along the walk ways. Hopefully I will complete the walkways this weekend.

Once the ceiling is painted I will then move the currently installed lights to just behind the valance and then obtain a few 5m LED light strips to complete the rest of the lighting in the room.

Here are a few pictures of the completed valance.

Over the last week or so I have been preparing the 2400 x 1200 x 3mm MDF sheets. They all needed to be painted white on one side (to reflect the light) and black on the opposite side.

Once I completed painted about 12 sheets of the MDF I then cut them into 400mm wide x 2400 long sections. As each sheet is 1220 wide I was able to get 3 x 400mm wide sheets from each larger sheet.

At this point I am super thankful for the help of my wife Michelle to helping feed the 12 sheets multiple times through the ever reliable Triton workbench.

The end result being 36 sheets ready to be installed.

As I planed to install the valance my self I found a I needed a 2nd pair of hands holding up the 2400mm long sheet. I quickly devised a jig using a old Black and Decker saw bench, a bunch of clamps and some timber. This mean that I was able to position one end of the valance near the ceiling and in roughly the correct spot and then start at the opposite end and screw the valance to the mounting timber I had installed some weeks ago. Got to love it when a plan comes together.!

Late yesterday and last night I installed all 36 odd sheets that were needed.

Then I cut up some extra smaller sheets that I then glue to the back of the valance to form a strong joint or connection between the each valance sheet. To do this I simply cut pre painted MDF sheets to 360mm x 200mm. Then with large amounts of wood glue, a few clamps and timber to hold it all in place I proceeded to connect all the sheets together.

Per the pictures I'm still working my way around the valance and gluing each part.

The next step is to paint all the silver screws that hold it to the mounting timber and to paint the walk ceiling along the walk ways. Hopefully I will complete the walkways this weekend.

Once the ceiling is painted I will then move the currently installed lights to just behind the valance and then obtain a few 5m LED light strips to complete the rest of the lighting in the room.

Here are a few pictures of the completed valance.

Tuesday, 22 October 2013

Turnout built test

Turnouts and more turnouts.

As the new layout is going to need almost double the number of turnouts that the old layout had, I decided that the most economical way to get the railroad built is to build my own turnouts. Kind of like "roll your own". Also there is a distinct shortage of Atlas Code 55 turnouts at present.

So I did some research and the bet method seems to be using the fastracks jigs and tools.

Luckily a friend had a relative unused jig hat I could procure. So once the procurement was completed, and time was available I set about building my first turn out.

The fastracks jig is made for Micro Engineering code 55 rail. However, I have plenty of short pieces from the old layout that I collected and plan to use all Atlas Code 55 rail for my turnouts. The Atlas code 55 rail has a slightly narrower rail head so the hand made ones should blend in well with the rest of the Atlas Code 55 rail on the layout.

All in all it took probably an hour and thirty minutes to build (including watching the how to videos from Fastracks) up to and not including adding the wooden ties to the turnout.

While it is not perfect and I need to make some adjustments, all in all I'm happy with the way it has come out.

You may also notice that the throw bar is wider than the standard Fastracks throw bar. I changed to the wider throw bar based on recommendations from others. This has a few advantages in that the solder joint to the point rails should be much stronger. Also the wider throw bar should better accommodate the hole needed for the tortoise switch machine under the layout. The standard PC board ties are very narrow and are prone to snapping in half when a hole is drilled for the tortoise throw rod.

When measured the wider throw bar is about 0.5mm wider than the factory built Atlas plastic throw bar so should not look out of place and is a full 1.5mm wider than the standard copper tie.

Here is a picture of the turnout and the jig.

Here is a picture of my turnout next to a stock standard Atlas turnout.

So there you have it. 1 turnout, this one is definately a test and wont go on the layout as it has a few flaws, now for the 48 that I need for the layout.

A further update. I have now built my second turnout and based on my learnings from the first this one is better and has much sharper frog points and much better point rails.

Thanks for checking in on the progress..

As the new layout is going to need almost double the number of turnouts that the old layout had, I decided that the most economical way to get the railroad built is to build my own turnouts. Kind of like "roll your own". Also there is a distinct shortage of Atlas Code 55 turnouts at present.

So I did some research and the bet method seems to be using the fastracks jigs and tools.

Luckily a friend had a relative unused jig hat I could procure. So once the procurement was completed, and time was available I set about building my first turn out.

The fastracks jig is made for Micro Engineering code 55 rail. However, I have plenty of short pieces from the old layout that I collected and plan to use all Atlas Code 55 rail for my turnouts. The Atlas code 55 rail has a slightly narrower rail head so the hand made ones should blend in well with the rest of the Atlas Code 55 rail on the layout.

All in all it took probably an hour and thirty minutes to build (including watching the how to videos from Fastracks) up to and not including adding the wooden ties to the turnout.

While it is not perfect and I need to make some adjustments, all in all I'm happy with the way it has come out.

You may also notice that the throw bar is wider than the standard Fastracks throw bar. I changed to the wider throw bar based on recommendations from others. This has a few advantages in that the solder joint to the point rails should be much stronger. Also the wider throw bar should better accommodate the hole needed for the tortoise switch machine under the layout. The standard PC board ties are very narrow and are prone to snapping in half when a hole is drilled for the tortoise throw rod.

When measured the wider throw bar is about 0.5mm wider than the factory built Atlas plastic throw bar so should not look out of place and is a full 1.5mm wider than the standard copper tie.

Here is a picture of the turnout and the jig.

I added some Atlas Code 55 ties to the 2 ends to keep things true.

So there you have it. 1 turnout, this one is definately a test and wont go on the layout as it has a few flaws, now for the 48 that I need for the layout.

A further update. I have now built my second turnout and based on my learnings from the first this one is better and has much sharper frog points and much better point rails.

Thanks for checking in on the progress..

Subscribe to:

Comments (Atom)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)