Valance install.

Over the last week or so I have been preparing the 2400 x 1200 x 3mm MDF sheets. They all needed to be painted white on one side (to reflect the light) and black on the opposite side.

Once I completed painted about 12 sheets of the MDF I then cut them into 400mm wide x 2400 long sections. As each sheet is 1220 wide I was able to get 3 x 400mm wide sheets from each larger sheet.

At this point I am super thankful for the help of my wife Michelle to helping feed the 12 sheets multiple times through the ever reliable Triton workbench.

The end result being 36 sheets ready to be installed.

As I planed to install the valance my self I found a I needed a 2nd pair of hands holding up the 2400mm long sheet. I quickly devised a jig using a old Black and Decker saw bench, a bunch of clamps and some timber. This mean that I was able to position one end of the valance near the ceiling and in roughly the correct spot and then start at the opposite end and screw the valance to the mounting timber I had installed some weeks ago. Got to love it when a plan comes together.!

Late yesterday and last night I installed all 36 odd sheets that were needed.

Then I cut up some extra smaller sheets that I then glue to the back of the valance to form a strong joint or connection between the each valance sheet. To do this I simply cut pre painted MDF sheets to 360mm x 200mm. Then with large amounts of wood glue, a few clamps and timber to hold it all in place I proceeded to connect all the sheets together.

Per the pictures I'm still working my way around the valance and gluing each part.

The next step is to paint all the silver screws that hold it to the mounting timber and to paint the walk ceiling along the walk ways. Hopefully I will complete the walkways this weekend.

Once the ceiling is painted I will then move the currently installed lights to just behind the valance and then obtain a few 5m LED light strips to complete the rest of the lighting in the room.

Here are a few pictures of the completed valance.

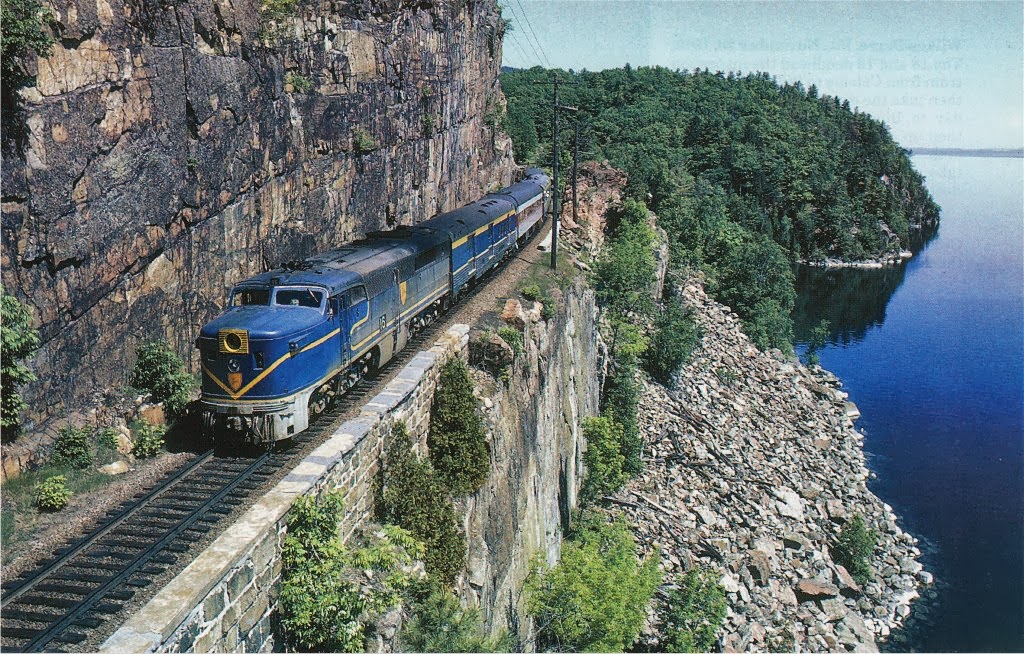

The Delaware & Hudson Rail Road 4th Sub is based on the Delaware & Hudson Railroad in New York state (USA) in the Whitehall area on the old D&H. The layout is N scale and I will use Digitrax DCC to run the layout. I am building the layout with full block signalling close to prototypical to the Delaware & Hudson per the D&H rule book dated 25th April 1948. Please enjoy the progress.

Thursday 31 October 2013

Tuesday 22 October 2013

Turnout built test

Turnouts and more turnouts.

As the new layout is going to need almost double the number of turnouts that the old layout had, I decided that the most economical way to get the railroad built is to build my own turnouts. Kind of like "roll your own". Also there is a distinct shortage of Atlas Code 55 turnouts at present.

So I did some research and the bet method seems to be using the fastracks jigs and tools.

Luckily a friend had a relative unused jig hat I could procure. So once the procurement was completed, and time was available I set about building my first turn out.

The fastracks jig is made for Micro Engineering code 55 rail. However, I have plenty of short pieces from the old layout that I collected and plan to use all Atlas Code 55 rail for my turnouts. The Atlas code 55 rail has a slightly narrower rail head so the hand made ones should blend in well with the rest of the Atlas Code 55 rail on the layout.

All in all it took probably an hour and thirty minutes to build (including watching the how to videos from Fastracks) up to and not including adding the wooden ties to the turnout.

While it is not perfect and I need to make some adjustments, all in all I'm happy with the way it has come out.

You may also notice that the throw bar is wider than the standard Fastracks throw bar. I changed to the wider throw bar based on recommendations from others. This has a few advantages in that the solder joint to the point rails should be much stronger. Also the wider throw bar should better accommodate the hole needed for the tortoise switch machine under the layout. The standard PC board ties are very narrow and are prone to snapping in half when a hole is drilled for the tortoise throw rod.

When measured the wider throw bar is about 0.5mm wider than the factory built Atlas plastic throw bar so should not look out of place and is a full 1.5mm wider than the standard copper tie.

Here is a picture of the turnout and the jig.

Here is a picture of my turnout next to a stock standard Atlas turnout.

So there you have it. 1 turnout, this one is definately a test and wont go on the layout as it has a few flaws, now for the 48 that I need for the layout.

A further update. I have now built my second turnout and based on my learnings from the first this one is better and has much sharper frog points and much better point rails.

Thanks for checking in on the progress..

As the new layout is going to need almost double the number of turnouts that the old layout had, I decided that the most economical way to get the railroad built is to build my own turnouts. Kind of like "roll your own". Also there is a distinct shortage of Atlas Code 55 turnouts at present.

So I did some research and the bet method seems to be using the fastracks jigs and tools.

Luckily a friend had a relative unused jig hat I could procure. So once the procurement was completed, and time was available I set about building my first turn out.

The fastracks jig is made for Micro Engineering code 55 rail. However, I have plenty of short pieces from the old layout that I collected and plan to use all Atlas Code 55 rail for my turnouts. The Atlas code 55 rail has a slightly narrower rail head so the hand made ones should blend in well with the rest of the Atlas Code 55 rail on the layout.

All in all it took probably an hour and thirty minutes to build (including watching the how to videos from Fastracks) up to and not including adding the wooden ties to the turnout.

While it is not perfect and I need to make some adjustments, all in all I'm happy with the way it has come out.

You may also notice that the throw bar is wider than the standard Fastracks throw bar. I changed to the wider throw bar based on recommendations from others. This has a few advantages in that the solder joint to the point rails should be much stronger. Also the wider throw bar should better accommodate the hole needed for the tortoise switch machine under the layout. The standard PC board ties are very narrow and are prone to snapping in half when a hole is drilled for the tortoise throw rod.

When measured the wider throw bar is about 0.5mm wider than the factory built Atlas plastic throw bar so should not look out of place and is a full 1.5mm wider than the standard copper tie.

Here is a picture of the turnout and the jig.

I added some Atlas Code 55 ties to the 2 ends to keep things true.

So there you have it. 1 turnout, this one is definately a test and wont go on the layout as it has a few flaws, now for the 48 that I need for the layout.

A further update. I have now built my second turnout and based on my learnings from the first this one is better and has much sharper frog points and much better point rails.

Thanks for checking in on the progress..

Monday 21 October 2013

Backboard Painting Completed

All a nice tinge on blue.

On Saturday I managed to complete the final layer of blue paint on all the backboards of the new peninsula's. Also with the help of the kids, we finished the painting of the legs / wall studs on the peninsula's black.

Now for the valance.

I'm really happy with the way things are turning out..

Looking forward to the end of base construction and painting so I can get into some track laying of the staging tracks.

Thanks for checking in..

On Saturday I managed to complete the final layer of blue paint on all the backboards of the new peninsula's. Also with the help of the kids, we finished the painting of the legs / wall studs on the peninsula's black.

Now for the valance.

I'm really happy with the way things are turning out..

Looking forward to the end of base construction and painting so I can get into some track laying of the staging tracks.

Thanks for checking in..

Tuesday 15 October 2013

Glue Trouble

Corners now complete.

After my last update I continued to putty up the gaps on the laminex corners.

I thought I was going well until I went into the shed the next morning to find one of the laminex corners had lifted and the glue had failed to bond to the shiny side of the laminex.

Turns out I should have taken advice from the layout construction master (aka Rod Warren).

I tried to find a glue that would stick to both paint and the laminex and did not use the glue that Rod suggested (mainly because the tin said it would not bond to paint).

Well the glue I found at bunnings looked to be the right one but alas it failed and I had to completely remove 2 of the 3 laminex corners and then go about removing the hard layer of glue from the MDF.

After an hour or so the work was complete and I set about using the glue Rod had suggested. This time, success, it stuck..

I then set about puttying up the gaps and also added many many more screws to hold the MDF backboards in place to make sure it does not warp..

Then I had to putty up and sand back the backboards to cover the screws..

After a fair bit of elbow grease the job is now done and the walls are ready for paint.

As you can see from the pictures, the corner pieces look to be set too high.. Don't worry, that's because the level of the base structure is at staging level and not the main deck level. Once the main deck is in, they will be covered and it will look nice...

Stay tuned for the next update.

After my last update I continued to putty up the gaps on the laminex corners.

I thought I was going well until I went into the shed the next morning to find one of the laminex corners had lifted and the glue had failed to bond to the shiny side of the laminex.

Turns out I should have taken advice from the layout construction master (aka Rod Warren).

I tried to find a glue that would stick to both paint and the laminex and did not use the glue that Rod suggested (mainly because the tin said it would not bond to paint).

Well the glue I found at bunnings looked to be the right one but alas it failed and I had to completely remove 2 of the 3 laminex corners and then go about removing the hard layer of glue from the MDF.

After an hour or so the work was complete and I set about using the glue Rod had suggested. This time, success, it stuck..

I then set about puttying up the gaps and also added many many more screws to hold the MDF backboards in place to make sure it does not warp..

Then I had to putty up and sand back the backboards to cover the screws..

After a fair bit of elbow grease the job is now done and the walls are ready for paint.

As you can see from the pictures, the corner pieces look to be set too high.. Don't worry, that's because the level of the base structure is at staging level and not the main deck level. Once the main deck is in, they will be covered and it will look nice...

Stay tuned for the next update.

Thursday 3 October 2013

Corner panels installed

Backboards and corners.

Over the last week or so, I have been busy working on completing the backboards / dividing walls for the layout and filling the various holes to cover the screws and plug up any gaps.

All the backboards are now done and I have cut gaps in the backboard where the staging tracks need to cross between the two sides of the backboards.

I have also completed painting the tops of the wall studs where they protrude from the tops of the walls.

Then the final task to complete before I set to work in painting the back boards / dividing wall is to fill in the corners. According to the local layout construction guru's, the best way to fill in the corners and make then concave, is to use laminex. When the laminex is installed, the best way is to use the back of the laminex facing outwards (to enable the paint to stick).

I have now installed the 3 pieces of laminex in the relevant corners.

Per the pictures, I have screwed temporary timber to the walls to ensure that the laminex stays where it should be while the glue cures.

One of the cool tools I purchased when I started the layout build that I now have in my kit bag, is a laser level. This cool little device sits on the top of a tripod and projects a horizontal and vertical laser beam. The cool part is that the beam is always exactly vertical / horizontal.. So installing the guide timber for the laminex was made very simple.. While this could have been done with a normal level, however the laser is just so precise. (The laser is similar to this one http://www.boschtools.com/PRODUCTS/MEASURINGANDLAYOUT/PAGES/BOSCHPRODUCTDETAIL.ASPX?pid=GLL+2-15)

Once the laminex is cured, the timber guides are then removed, the holes plugged up (from the screws used to hold the timber to the wall) and then the painting can begin..

Thanks for dropping by.

Next time.. Painting and valance.

Over the last week or so, I have been busy working on completing the backboards / dividing walls for the layout and filling the various holes to cover the screws and plug up any gaps.

All the backboards are now done and I have cut gaps in the backboard where the staging tracks need to cross between the two sides of the backboards.

I have also completed painting the tops of the wall studs where they protrude from the tops of the walls.

Then the final task to complete before I set to work in painting the back boards / dividing wall is to fill in the corners. According to the local layout construction guru's, the best way to fill in the corners and make then concave, is to use laminex. When the laminex is installed, the best way is to use the back of the laminex facing outwards (to enable the paint to stick).

I have now installed the 3 pieces of laminex in the relevant corners.

Per the pictures, I have screwed temporary timber to the walls to ensure that the laminex stays where it should be while the glue cures.

One of the cool tools I purchased when I started the layout build that I now have in my kit bag, is a laser level. This cool little device sits on the top of a tripod and projects a horizontal and vertical laser beam. The cool part is that the beam is always exactly vertical / horizontal.. So installing the guide timber for the laminex was made very simple.. While this could have been done with a normal level, however the laser is just so precise. (The laser is similar to this one http://www.boschtools.com/PRODUCTS/MEASURINGANDLAYOUT/PAGES/BOSCHPRODUCTDETAIL.ASPX?pid=GLL+2-15)

Once the laminex is cured, the timber guides are then removed, the holes plugged up (from the screws used to hold the timber to the wall) and then the painting can begin..

Thanks for dropping by.

Next time.. Painting and valance.

Subscribe to:

Posts (Atom)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)