LED Lighting under the upper deck

This week I completed the install of the LED lighting under the upper deck. This lighting is intended to be supplementary to the main room lighting so that the buildings and scenery at the back of the lower level can be seen.

The first 3 pictures show the LED lighting with the main room lighting turned on.

The next 2 pictures show the LED lighting with the main room lighting turned off.

Stay tuned for more updates.

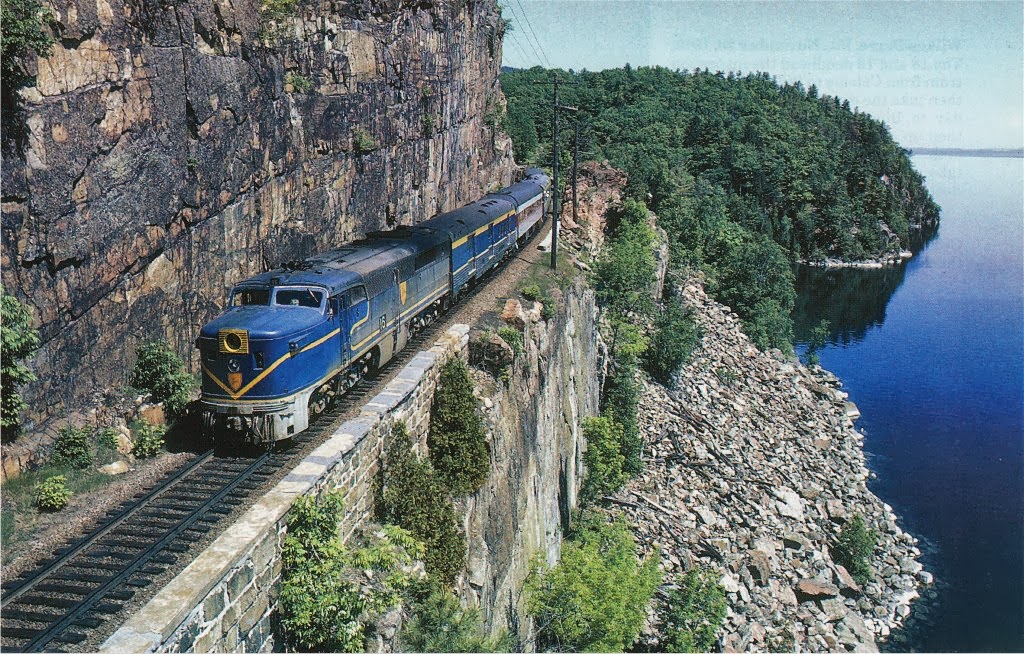

The Delaware & Hudson Rail Road 4th Sub is based on the Delaware & Hudson Railroad in New York state (USA) in the Whitehall area on the old D&H. The layout is N scale and I will use Digitrax DCC to run the layout. I am building the layout with full block signalling close to prototypical to the Delaware & Hudson per the D&H rule book dated 25th April 1948. Please enjoy the progress.

Tuesday 19 September 2017

Monday 11 September 2017

Whitehall Yard almost complete

Track gang hard at work.

The track gang in Whitehall has been hard at work over the last 24 hours.

The 9 new turnouts, plus 1 I found in a box, have now been installed in Whitehall.

This all but completes the yard build. I just need 2 more turnouts for the Whitehall engine facility and then it will be complete.

Here are a few pictures of the completed track work.

The next step is to install MP1's on the 10 new turnouts and provide power to the new section. This will happen later this week.

Stay tuned for the next update.

The track gang in Whitehall has been hard at work over the last 24 hours.

The 9 new turnouts, plus 1 I found in a box, have now been installed in Whitehall.

This all but completes the yard build. I just need 2 more turnouts for the Whitehall engine facility and then it will be complete.

Here are a few pictures of the completed track work.

The next step is to install MP1's on the 10 new turnouts and provide power to the new section. This will happen later this week.

Stay tuned for the next update.

Thursday 7 September 2017

Staging expansion and more turnouts.

Major works on the D&H

Over the last few weeks I have had a fair bit of spare time after being made redundant from my job after 28 years of service. All is positive and am looking at it as a new opportunity...

The net effect is that I have had some time to reflect on work as a whole and spend a fair bit of time in the shed working on the D&H.. Also have spent a fair bit of time helping John Colliver with the move of Rod Warren's SFRSD and also helping Jason on his HO Reading layout.

Staging changes.

After the last shake down of the D&H by Rod, Bill and John Fahey, I found that I did not like the way I had set up the staging yards of the layout with only 2 tracks being return loops and the other 3 being dead end tracks. I felt this was going to lead to problems with track lengths and turning trains etc. I decided I would modify both upper and lower staging so that all 5 tracks were made return loops. After a fair bit of planning, I devised the track plan and set about updating it.

Here is the Anyrail plan of the original staging, upper and lower.

Here are the revised plans.

Here are a few pictures showing the completed track layout.

These changes to staging will make things much easier for trains to enter staging and be ready to run again and will also fix the issue that I had where some tracks were too short to hold a full length train.

Turnout driver changes / SE8C

As the layout has a large amount of electronics under it for JMRI, Signals, block detection etc, I found that I had 2 x SE8C's that I was using for signals but could not use them for turnout drivers as the new MP1's that I am using are not wired the same as a tortoise and the newer MP5's that can be wired as a tortoise cant be driven by the SE8C due to the low voltage output of the SE8C. So I set about finding a way to drive the MP1 turnout machine via a Arudino relay boards.. The relay boards have an TTL level opto coupler input that drives 12v SPDT relays. These relay boards are perfect for driving the MP1 that needs a SPDT switch.

I found that with the help of a resistor 1 of the 2 outputs that the SE8C has for the tortoise machine can drive the opto coupler that is on the relay board. This then enabled me to drive the MP1's from the SE8C with the help of the relay board.

Here are a few pictures of the set up.

here we see 2 x SE8C's each driving their own 8 port relay board.

The small board in the middle just holds 8 x 22K resistors that enable the output of the SE8C to drive the opto coupler.

More Turnouts.

Now that upper and lower staging are updated and note that I am using Atlas code 55 turnouts in staging. All other places on the lower or main level have hand laid turnouts using fasttracks #6 jig, I have used up all the turnouts I had made. It was now time to get cracking to make more turnouts. This week I set about making more and over 2 days I have made 9 turnouts. I then exhausted the supplier of copperhead turn out ties.. So while I wait for them to arrive, I figured I would fully prepare the new 9 turnouts ready for install.

Per the progress pictures, they are cleaned and I ahve installed the wood ties ready for painting. I have installed masking tape in the point rail / check rail area so that paint does not get into this gap so as to not make the turnouts stick when the rails are together and under pressure. There is no requirement for the check rail and point rail to conduct power for the rest of the turnout due to the design of the turnout, therefore the masking tape is to stop them from sticking when in place on the layout.

Here are a few progress pictures of the turnouts.

Ready for cleaning (to remove excess flux etc)

All clean

Wooden ties and masking tape installed, ready for painting.

Well, thats it for now.. In the next update I will show the MP1 and MP5 turnout machines and how they work..

Thanks for visiting..

Over the last few weeks I have had a fair bit of spare time after being made redundant from my job after 28 years of service. All is positive and am looking at it as a new opportunity...

The net effect is that I have had some time to reflect on work as a whole and spend a fair bit of time in the shed working on the D&H.. Also have spent a fair bit of time helping John Colliver with the move of Rod Warren's SFRSD and also helping Jason on his HO Reading layout.

Staging changes.

After the last shake down of the D&H by Rod, Bill and John Fahey, I found that I did not like the way I had set up the staging yards of the layout with only 2 tracks being return loops and the other 3 being dead end tracks. I felt this was going to lead to problems with track lengths and turning trains etc. I decided I would modify both upper and lower staging so that all 5 tracks were made return loops. After a fair bit of planning, I devised the track plan and set about updating it.

Here is the Anyrail plan of the original staging, upper and lower.

Here are the revised plans.

Here are a few pictures showing the completed track layout.

These changes to staging will make things much easier for trains to enter staging and be ready to run again and will also fix the issue that I had where some tracks were too short to hold a full length train.

Turnout driver changes / SE8C

As the layout has a large amount of electronics under it for JMRI, Signals, block detection etc, I found that I had 2 x SE8C's that I was using for signals but could not use them for turnout drivers as the new MP1's that I am using are not wired the same as a tortoise and the newer MP5's that can be wired as a tortoise cant be driven by the SE8C due to the low voltage output of the SE8C. So I set about finding a way to drive the MP1 turnout machine via a Arudino relay boards.. The relay boards have an TTL level opto coupler input that drives 12v SPDT relays. These relay boards are perfect for driving the MP1 that needs a SPDT switch.

I found that with the help of a resistor 1 of the 2 outputs that the SE8C has for the tortoise machine can drive the opto coupler that is on the relay board. This then enabled me to drive the MP1's from the SE8C with the help of the relay board.

Here are a few pictures of the set up.

here we see 2 x SE8C's each driving their own 8 port relay board.

The small board in the middle just holds 8 x 22K resistors that enable the output of the SE8C to drive the opto coupler.

More Turnouts.

Now that upper and lower staging are updated and note that I am using Atlas code 55 turnouts in staging. All other places on the lower or main level have hand laid turnouts using fasttracks #6 jig, I have used up all the turnouts I had made. It was now time to get cracking to make more turnouts. This week I set about making more and over 2 days I have made 9 turnouts. I then exhausted the supplier of copperhead turn out ties.. So while I wait for them to arrive, I figured I would fully prepare the new 9 turnouts ready for install.

Per the progress pictures, they are cleaned and I ahve installed the wood ties ready for painting. I have installed masking tape in the point rail / check rail area so that paint does not get into this gap so as to not make the turnouts stick when the rails are together and under pressure. There is no requirement for the check rail and point rail to conduct power for the rest of the turnout due to the design of the turnout, therefore the masking tape is to stop them from sticking when in place on the layout.

Here are a few progress pictures of the turnouts.

Ready for cleaning (to remove excess flux etc)

All clean

Wooden ties and masking tape installed, ready for painting.

Well, thats it for now.. In the next update I will show the MP1 and MP5 turnout machines and how they work..

Thanks for visiting..

Subscribe to:

Posts (Atom)